Q & A

Types of Life Cycle Assessment

Choosing the right method for your organization

About Environmental Input-Output Life Cycle Assessment (IO-LCA)

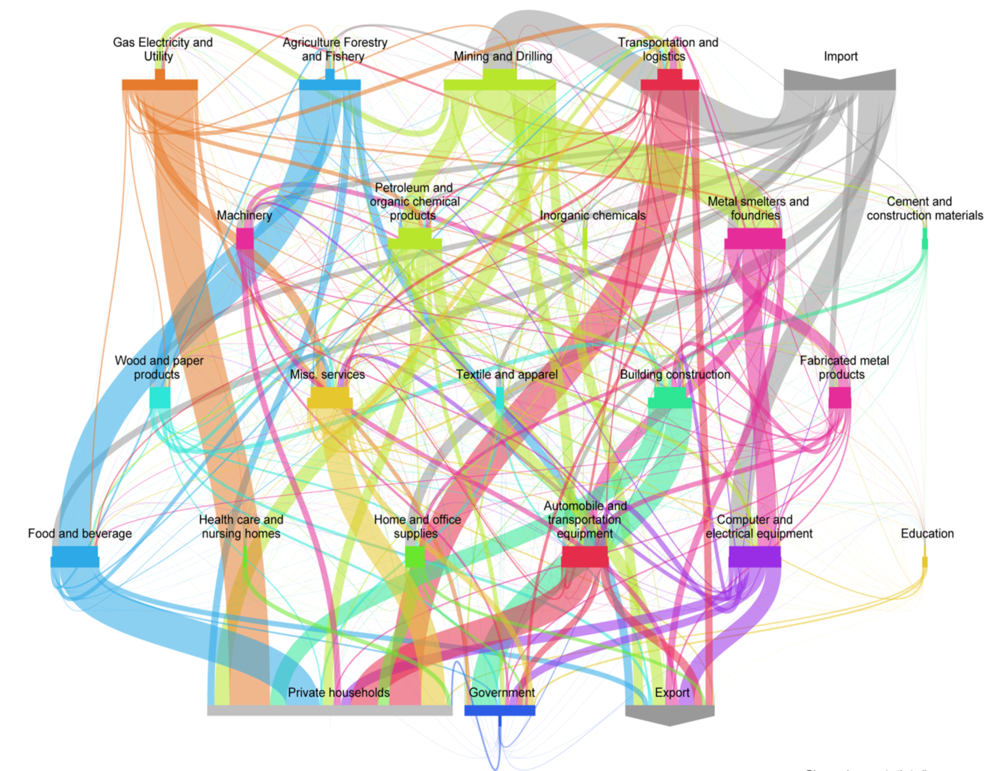

This Sankey diagram shows how environmental impacts are generated and passed down throughout the supply chain of the U.S. economy. The paper where this diagram first appeared earned IERS (VitalMetrics) the 2011 Wassily Leontief Memorial Prize from the International Input-Output Association.

An Environmental Input-Output Life Cycle Assessment (IO-LCA) involves the use of aggregate sector-level data to quantify the amount of environmental impact that can be directly attributed to each sector of the economy and how much each sector purchases from other sectors in producing its output. IO-LCA analysis traces out the various economic transactions, resource requirements and environmental emissions (including all the various manufacturing, transportation, mining and related requirements) required for producing a particular product or service.

We perform IO-LCA projects using our peer-reviewed, CEDA database.

Process LCA

Life cycle primary energy consumption of one window frame over an 80-year service life functional unit.

Process-level life cycle assessment (p-LCA) is a widely used science-based method of quantifying an array of environmental impacts associated with a product’s production, use, and end-of-life management. It is used by a variety of organizations in a number of different applications. Private firms use it for product development and carbon management, and government agencies use it to inform policy decisions.

For example, VitalMetrics conducted a p-LCA focusing on the primary energy consumption of window frames made from three different materials and identified the material with the largest life-cycle energy savings.

Hybrid LCA

Hybrid LCA combines IO-LCA and p-LCA to reduce the time and effort needed and to improve completeness and precision.

Phase One – IO-LCA

Using spend data and IO-LCA, our team quickly produce a rough sketch of your organization’s or product’s footprint throughout the supply chain. This approach utilizes only an organization’s general ledger and maps it to CEDA for a “big picture” view, which can be depicted as a low-resolution but wide-angle picture shown below. This dramatically reduces the resources usually required to complete a supply chain sustainability impact assessment. It also prioritizes the flows or life-cycle stages that need to be analyzed more in detail during the next phase.

Phase Two – Process-LCA

Focusing on the supply chain “hot spots” that were identified during the first phase of hybrid LCA, we apply process-LCA approach to refine our estimates. We identify best available data and methods to improve precision for the targeted hotspots. This can be depicted as the high-resolution pictures for key components as shown below. The ability to prioritize hotspots quickly using IO-LCA reduces the costs and efforts needed for undertaking process-LCA, while maintaining completeness of the system description.

Phase Three - Integrated Hybrid LCA

Integrating IO-LCA and p-LCA, we are able to improve the precision of the analysis focusing on the hotspots, while maintaining the big picture, just like the picture shown here.

Quantifying supply chain impacts is the most time-consuming yet uncertain part of an organization's sustainability assessment. In order to estimate supply-chain impacts, a list of inputs to an organization that includes products, services, equipment, and logistics needs to be compiled.

The Integrated Hybrid Approach that VitalMetrics developed delivers detailed LCA results while saving time and resources needed for quality LCA results.